Press Hardening

Project example electrolytic corrosion

• Development of protective coatings

Issue

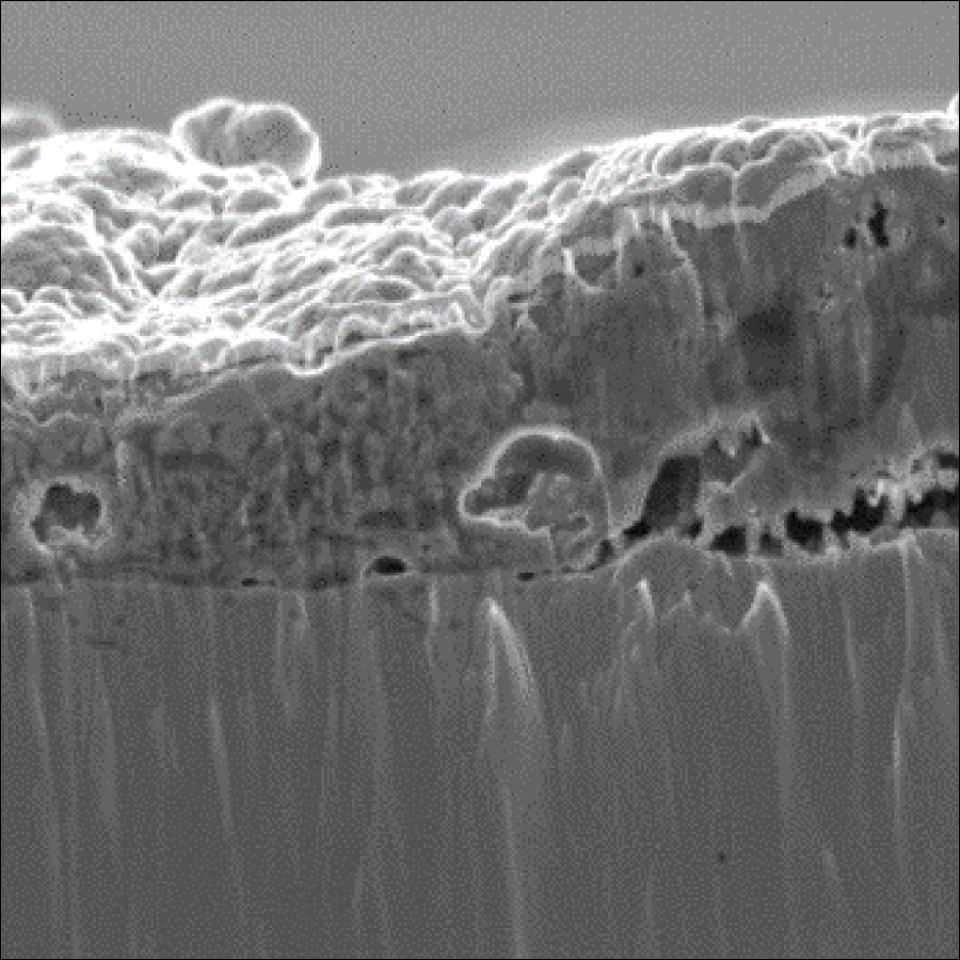

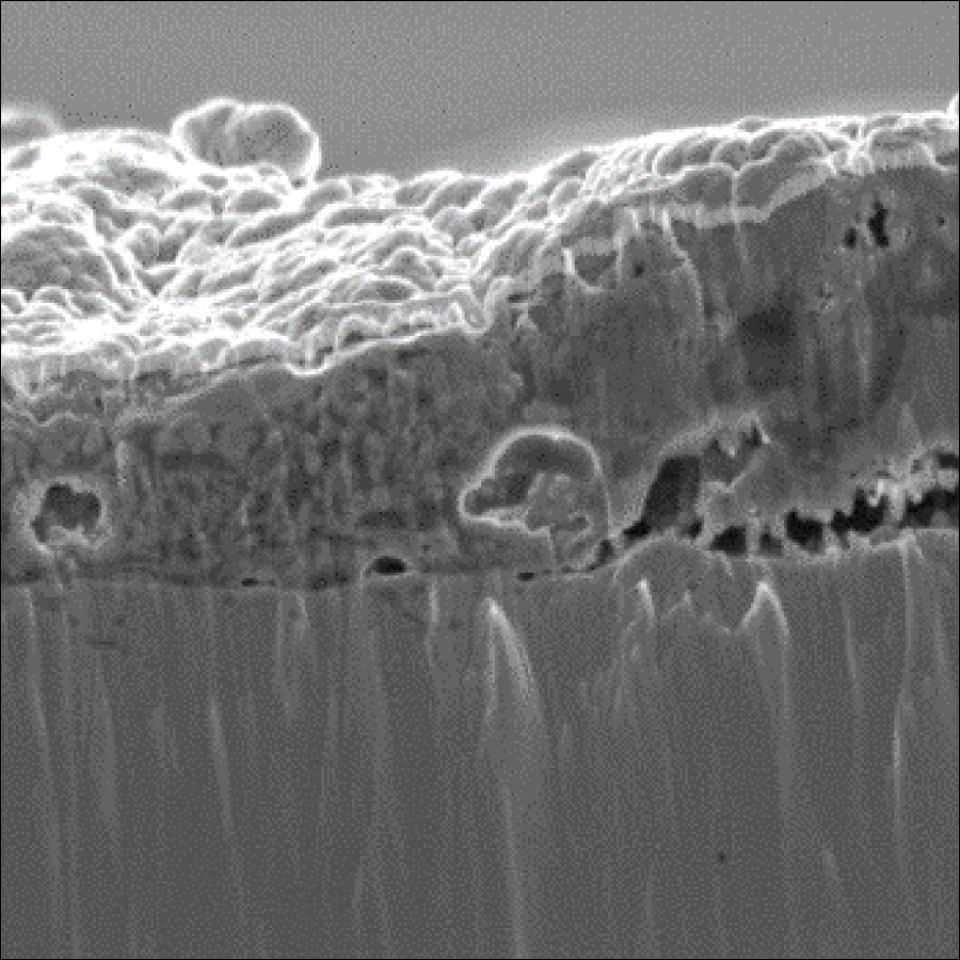

- Press hardening is used for the manufacturing of high-strength steel components in the automotive industry

- Without an appropriate protective coating severe scaling occurs at the required working temperatures (>900°C)

- Previous coating systems have various disadvantages (e.g. problems with post-processing such as welding or painting)

Approach

- Development of a multi-layer system using oxide nano-particles, which suppresses scaling and enables good processability of the sheets

Customer Benefit

- Significant reduction in scaling and surface decarburisation during the forming process

- Further processing by means of resistance spot welding and laser welding is possible