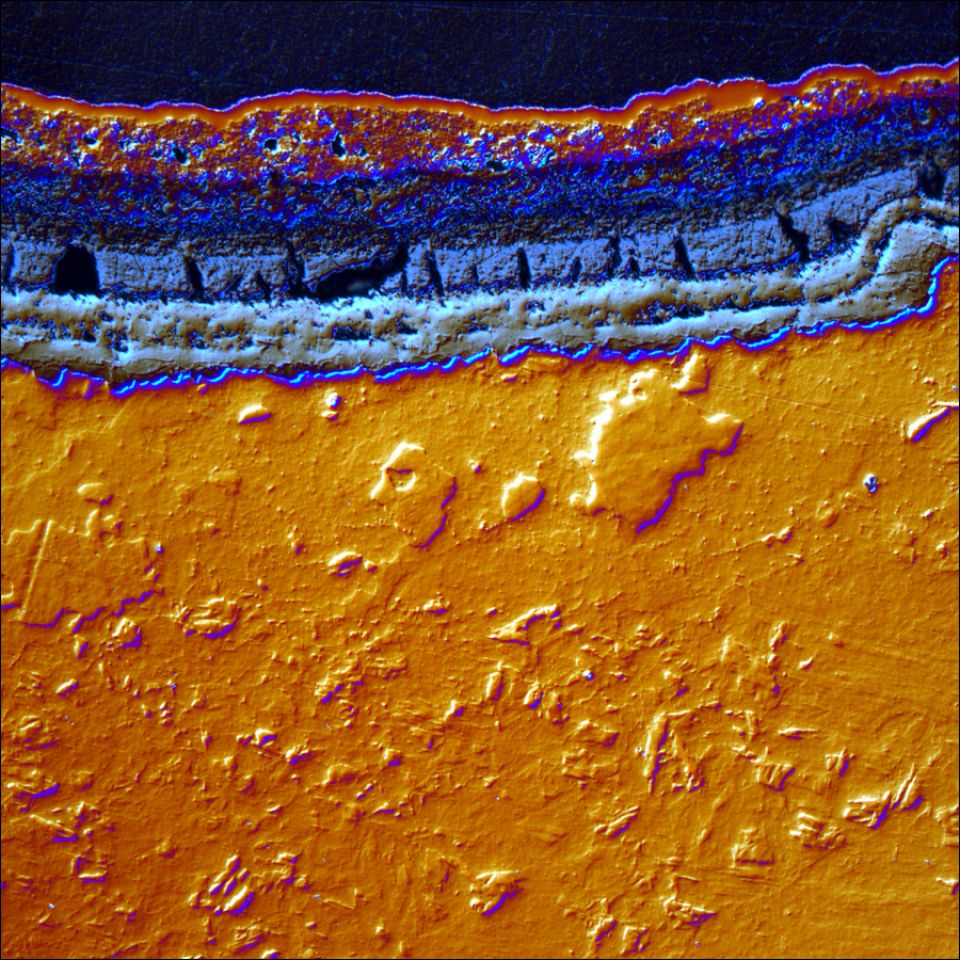

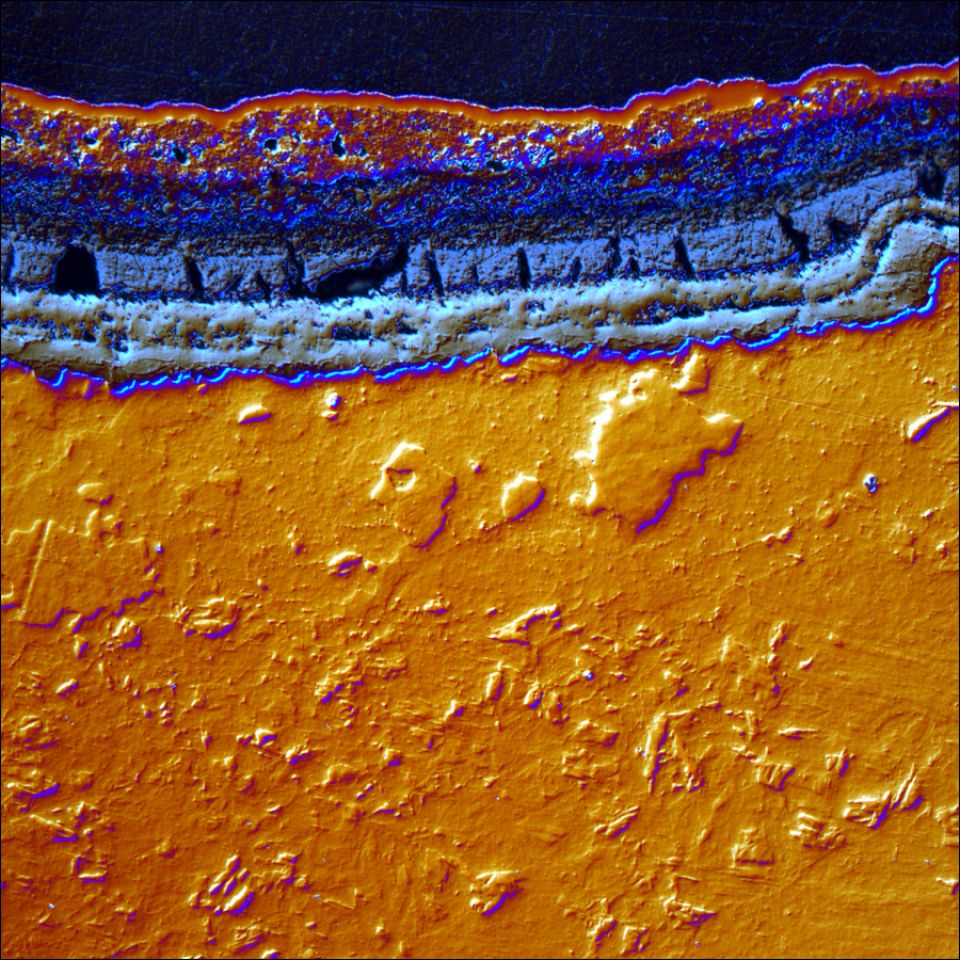

Corrosion Under Slag Deposits During Partial Oxidation

Project example high-temperature corrosion

• Damage assessment

• Development of corrosion protection coatings

Issue

- Corrosion of waste heat boiler tubes due to deposits and ashes, which accumulate in the partial oxidation process of heavy oils and are deposited on the colder tube surfaces

- Heavy oils contain large amounts of sulphur and heavy metal residues, especially vanadates, which lead to increased corrosion attack

Approach

- Long-term tests under conditions close to the application and metallographic characterization of various materials led to a significantly improved understanding of the underlying corrosion process

- No economically viable, corrosion resistant material could be found

- Protective coatings and a coating process for the internal coating of pipes and plant components was developed based on laboratory tests and thermodynamic calculations

Customer Benefit

- Up-scaling of the coating process for internal coating of tubes (of approx. 2 m wide and approx. 8 m high pipe coils)

- Prevention of corrosion damages and plant downtimes through an effective corrosion protection concept for cost-effective materials

- Design of experiments and material selection is supported by thermodynamic calculations