Friction-Stir Welding

Project example electrolytic corrosion

• Materials testing

• Development and qualification of corrosion-resistant coating concepts

Issue

- Friction-stir welding is used to obtain welded joints of different metals (e.g. Al / Mg or Al / steel).

- Galvanic corrosion can occur in the welding zone when using such connections

- Investigating the increased corrosion in the seam area in the case of different welded joints, also dependent on welding parameters

Approach

- Determination of Volta potential differences in the welding zone by means of a Scanning Kelvin Probe (SKP)

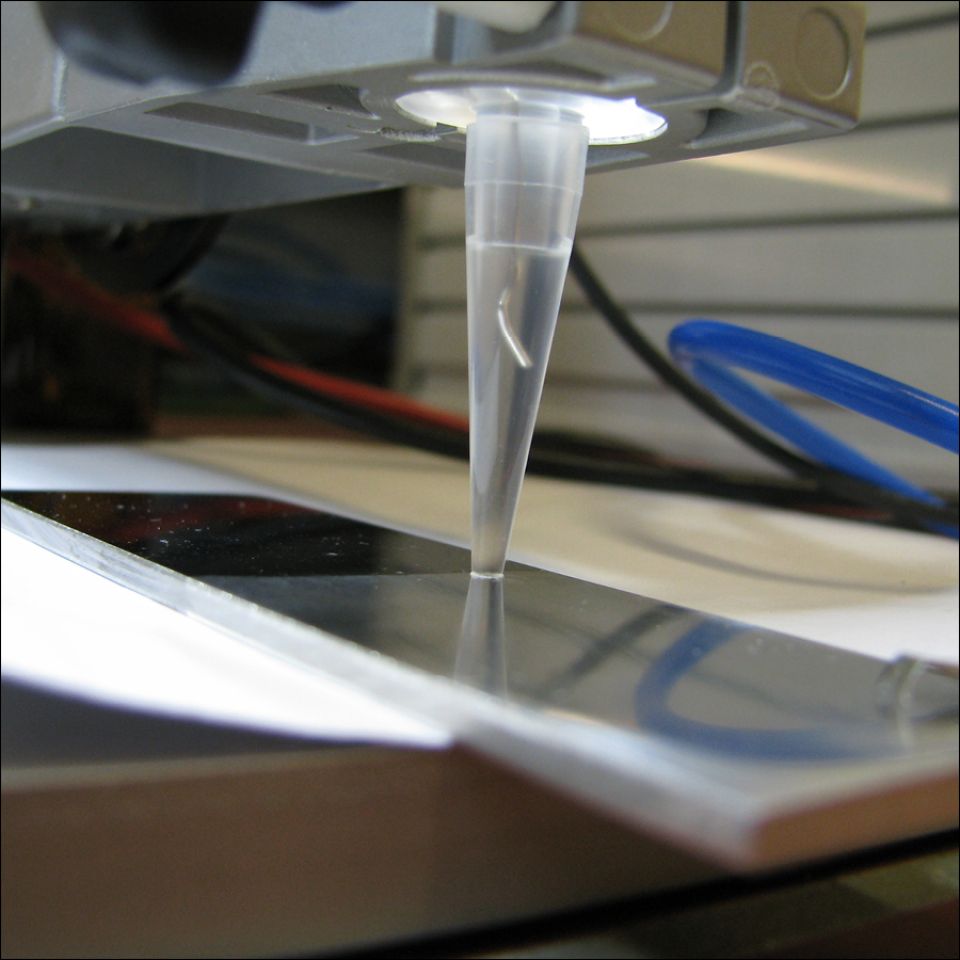

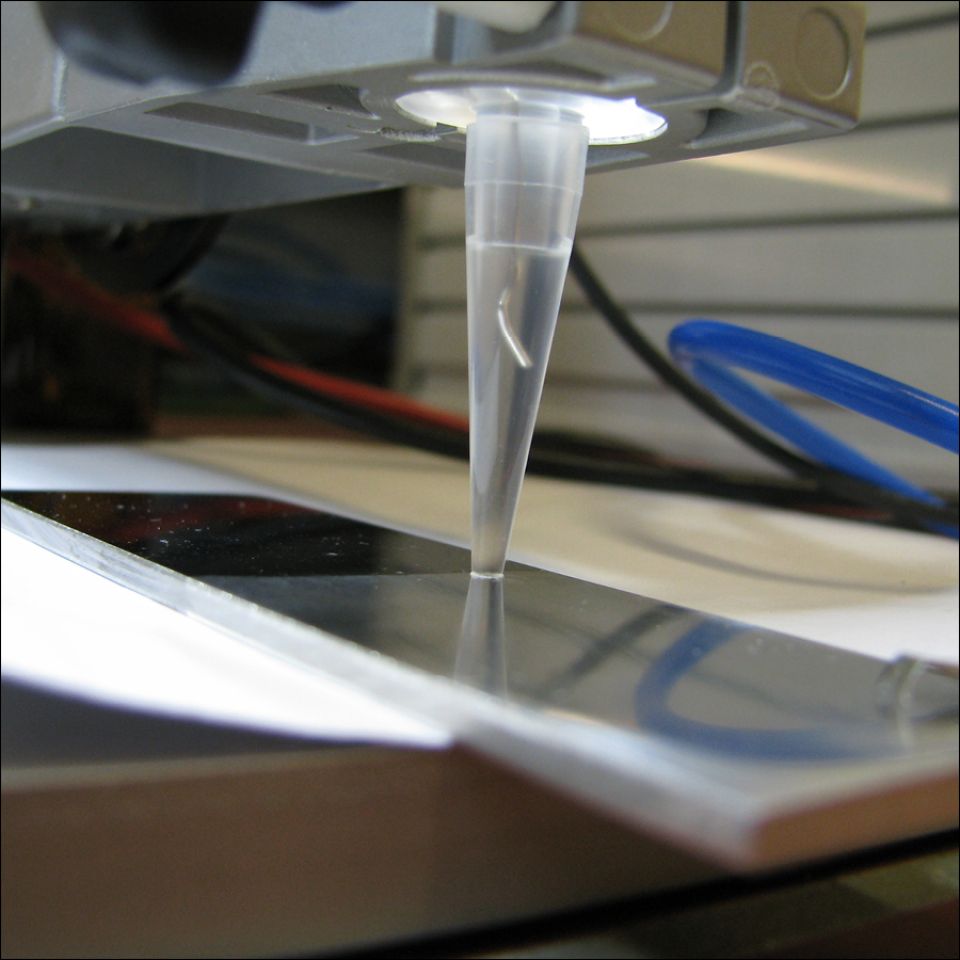

- Local electrochemical measurements (open circuit potential, current density-potential curves) on different spots of the welding seam using an electrochemical mini-cell

- SEM / EDX analysis to investigate the formation of intermetallic phases

Customer Benefit

- The risk of galvanic corrosion in the joining zone can be assessed as a function of the joining partners and parameters

- Correlation of the corrosion behaviour with the microstructure of the joining zone is possible