Technical Equipment and Methods

The DECHEMA Corrosion Center offers a wide range of state-of-the-art technical equipment and methods, which are available within the framework of projects and industrial cooperation.

Metallography and Characterization

Metallography

- Classical and non-aqueous metallography incl. target preparation

- Interference Layer Metallography

- Light/ Optical microscopy and stereomicroscopes (Leica)

- Scanning electron microscopes with energy dispersive X-ray analysis (EDX) (Hitachi Flex SEM 1000II), as well as electron backscatter diffraction (EBSD), scanning transmission detector (STEM) and in-situ high temperature stage (Hitachi SU 5000)

- Chemical Analysis

- Electron probe microanalysis (EPMA) with wavelength dispersive X-ray analysis (WDS) (JEOL JXA-8100)

- Scanning electron microscopes with energy dispersive X-ray analysis (EDS) (Hitachi Flex SEM 1000II)

- Spark Emission Spectrometer (OES) (Ametek SPECTROMAXx)

- Atomic Absorption Spectroscopy (AAS) (Varian AA 240 FS)

- Mass spectrometry with inductively coupled plasma (ICP-MS), optionally with upstream ion chromatography

- Ion chromatography (anions and cations)

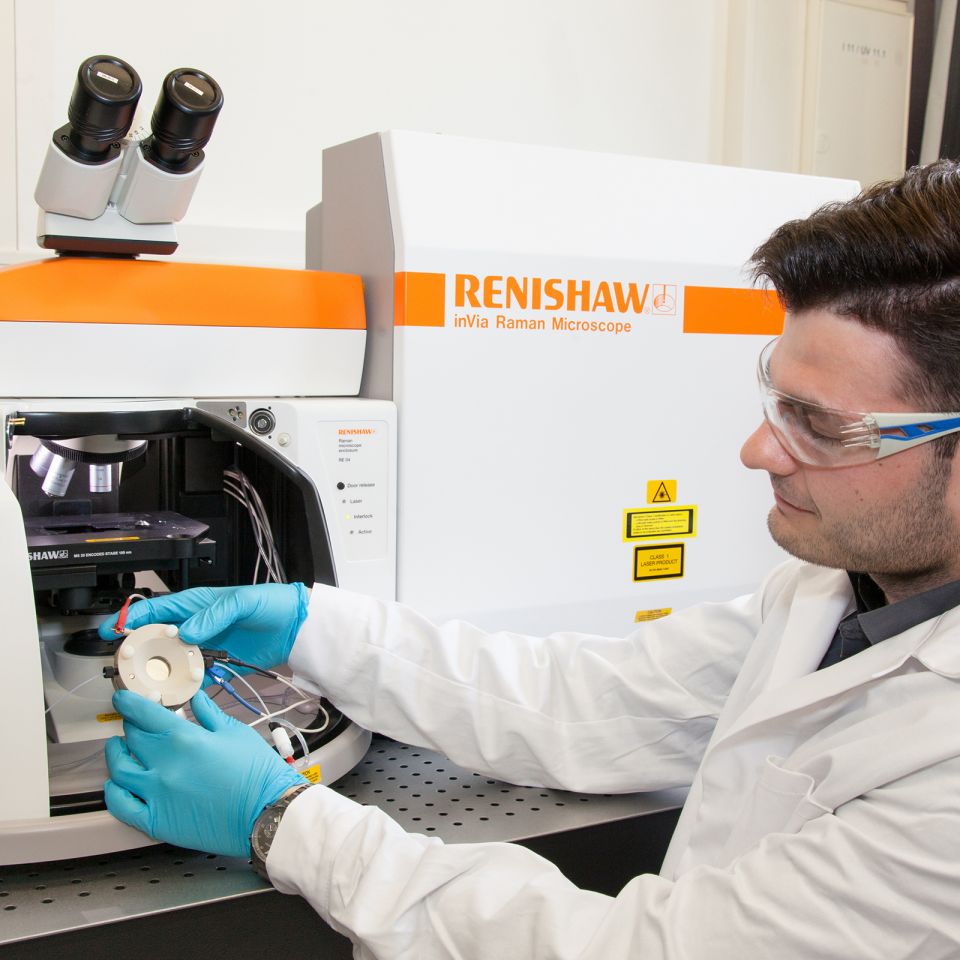

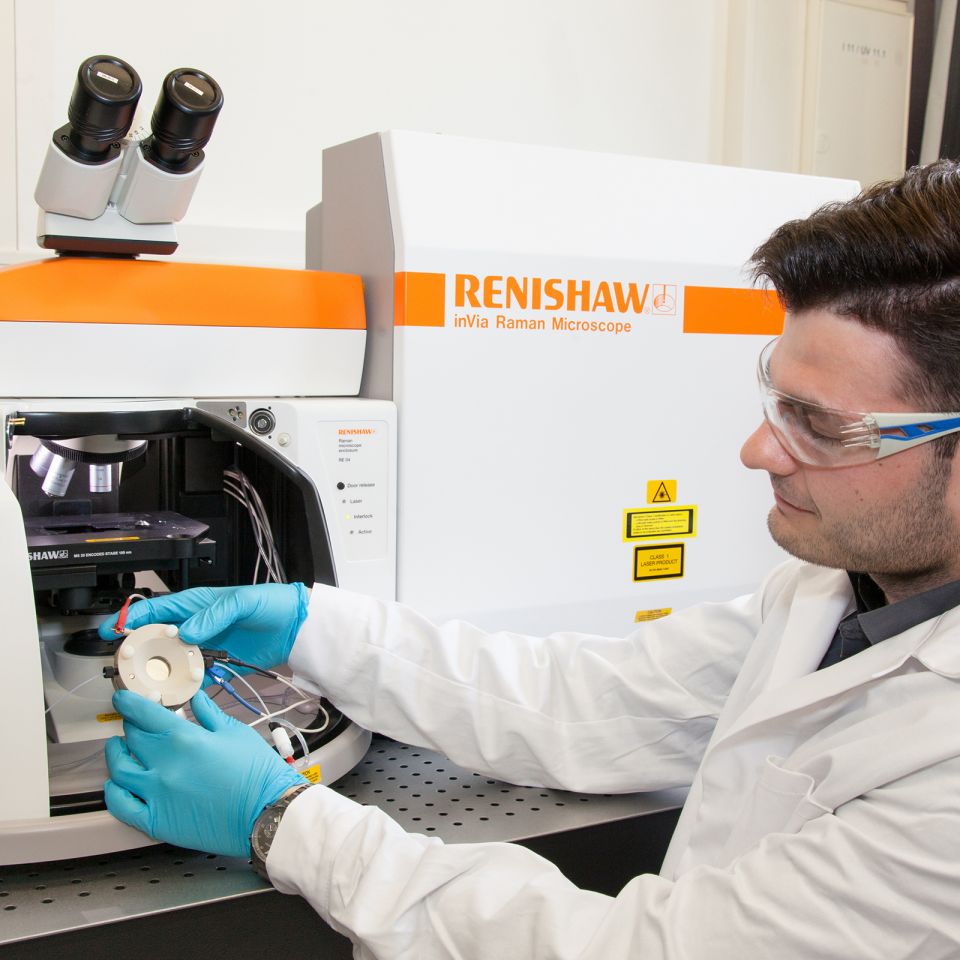

- Structural Analysis

- X-ray diffractometer (XRD) with Göbel mirror and in-situ high temperature analysis (Bruker D8 Advance)

- Confocal Raman microscope with in-situ spectroscopy (Renishaw RE 04)

Surface Characterization

- Confocal Laser Scanning Microscope (CLSM) (Leica TCS SP8)

- Contact angle measurement (also for temperatures up to 1200 °C)

- Profilometer (Mahr MarSurf GD 26)

- Linear abrasion tester (Linear Taber Abraser)

- Particle size and zeta potential measurement system by dynamic light scattering (DLS) (Malvern Zetasizer Nano)

Mechanical Characterization

- Small load hardness testing

- Nanoindenter (Anton Paar NHT³)

- Tribometer (Nanovea T5)

- 4-point bending test benches

- Mechanical testing machines up to 10 kN

Thermal Analysis

- Simultaneous thermal analysis with differential thermal analysis (DTA), differential scanning calorimetry (DSC) and thermogravimetry (TG) (Netzsch STA 449 F3)

- Dilatometer (Linseis)

- Dilatometer (Linseis)

Materials Consulting

Databases

- DECHEMA Corrosion Handbook

Software

- JMatPro

- FactSage

- ThermoCalc

Electrolytic Corrosion Testing

- Potentiostats for high and low impedance applications to be used in the following electrochemical methods: current density potential curves; zero resistance amperometry (ZRA), cyclic voltammetry (CV), electrochemical impedance spectroscopy (EIS)

- Electrochemical quartz microbalance (EQCM)

- Rotating ring-disc electrode (RRDE)

- Scanning Kelvin probe

- Salt spray chamber

High-Temperature Corrosion Testing

- Isothermal furnaces up to 1600 °C (tube and chamber furnaces), aggressive atmospheres and salt deposits possible

- Cyclic furnaces up to 1300 °C (up to 1000 °C with aggressive atmospheres and salt deposits)

- Pressure equipment up to 30 bar (maximum temperature 800 °C, at 15 bar maximum temperature 1000 °C)

- Thermobalances

- Induction furnace

- In-situ acoustic emission analysis

- High temperature tribometer

- Creep test benches

Protective Coating and Alloy Development

- Pack cementation

- Slurry coating

- Four-source magnetron sputter system

- Dip Coater

- Spin Coater

- Doctor blade coater

- Screen printing plant

- High voltage/high current potentiostats for anodization

- Arc melting furnace (up to 3000 °C)

- Vacuum induction melting furnace (up to 2000 °C)

Production Engineering Methods and Equipment

- Nd-YAG laser for microstructuring

- CO2 laser for precise cutting of components

- Mechanical precision processing machines

- (High power) ultrasonic finger

- Spray system with ultrasonic head

- Laboratory hot press

- Calender

- Ball mill

- Glovebox